HTT OXYMO™ EAF BURNER

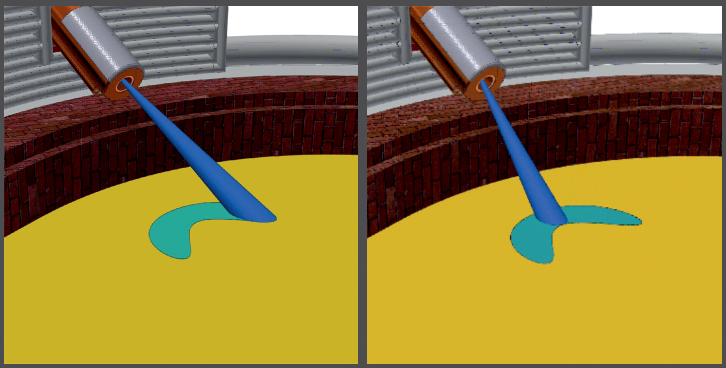

New Level of chemical energy efficiency with oxygen jet and flame in motion

FEATURES

• Flame and oxygen jet travelling left to right in the furnace with up to 30° angle

• Downward firring / jet angle range 40 to 52 °

• Steep oxygen impact angle in lance mode

• Off set heat release and soft flame envelope

• Made of forged copper with high speed water cooling

• Smooth nozzles motion with low force

• Furnace tight installation

• Integrated carbon and lime lances

• No moving external parts

• Replaceable nozzle assembly

BENEFITS

• Superior burner energy efficiency – 5 x larger volume of scrap in contact with flame

• Superior oxygen efficiency in lance mode – short distance and steep impact angle of scrap in contact with flame

• Better bath mixing

• Low electrodes consumption

• Moving oxygen / gas nozzles inside the burner – all connections are static

• Lower refractory wear

• Lower energy consumption

– shorter power on time

Burner internal nozzles motion will be performed via small hydraulic actuator integrated to burner structure on the cold side of the furnace. The burner design is done that only one hose in the back moves, all other connections are stationary, simple and compact installation. Available as compact unit with two replaceable lances for carbon and lime injection

For download, brochure click here: HTT OXYMO BROCHURE (PDF)